Overview

Citizen Lathe area of manufacturing floor adding a new lathe (5 —> 6 machines)

Plenty of room for improvement in product and operator workflow maps

Workstations are cluttered and unorganized

Process

Recorded Activity of the Operator (AOO) and Activity of the Product (AOP) for major product families

Indicated areas for improvement in floor layout, workstation redesign, and time management with product planning by analyzing AOO and AOP videos

Created workflow maps from AOP videos, revealing wasted product movement and Work In Progress (WIP) stations

Redesigned floor layout to make room for new machine and improve product workflows

Organized workstations using 6S techniques to remove unnecessary tools and materials

Designed and ordered custom shadow boards for tools and desk supplies

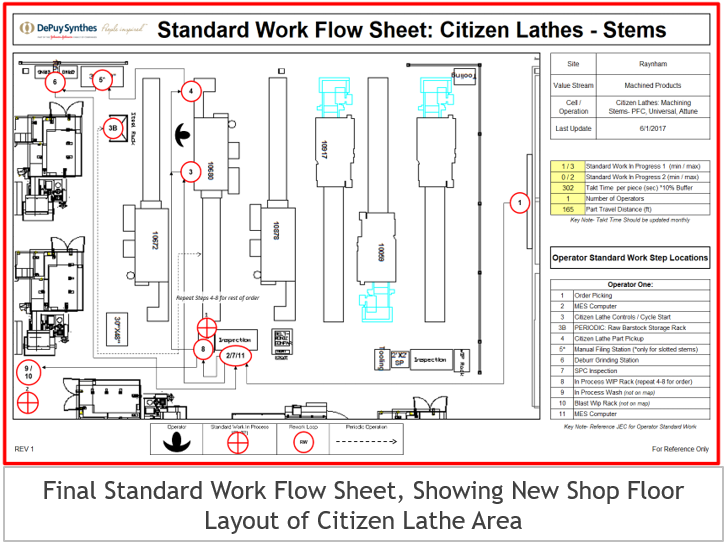

Final Standard Work Flow Sheet created for the new Citizen Lathe area, with new floor layout, ,custom template and all operator location steps

One of the machine operators working with the new floor layout

Backend process workstation, highlighting 6S integration and organization

Pictured above are the two shadow boards designed- the top image is for lathe tooling, and the bottom image is for go/no-go pin gauges

cOMPLICATIONS

Filming and analyzing AOO & AOP took a tremendous amount of time (videos were 3-6 hrs long), delaying the project

Had to order new workstation desks that were smaller and able to fit in the new layout design

Shadow board production by third-party vendor were made incorrectly and had to be redesigned and reordered

Results

New floor layout improved product flow and fit new lathe machine to increase production capacity

Shadow boards and organized workstations increased efficiency and achieve more continuous flow

Designed new Standard Work Flow Sheet and Six Sigma posters, to be implemented in all shop floor areas in future projects

Skills Developed

Lean techniques for improving efficiency of production in manufacturing processes

Six Sigma process of improving appearance and performance of workstations

Design of manufacturing floor to maximize workflows